Trenchless Sewer Repair

When It Comes to Sewer Line Repair Service, You Have Options!

Most property owners are familiar with the traditional trenching method for sewer drain repair, but as a modern drain repair business, the Sewer Cleaning Company also offers trenchless repair options. Learn more about both to help you decide which is best for your needs.

Traditional Sewer Drain Repair

We will almost always recommend trenchless sewer drain repair for its ease, affordability, and efficiency, but in some cases, traditional trenching methods are the only option that will get you the results you're looking for. Open trenching requires heavy duty machinery–like a backhoe or other digging equipment–to expose the sewer that needs to be repaired.

These are the main reasons why you may need to opt for traditional sewer drain repair:

- Existing drain is badly damaged, collapsed, corroded, incorrectly installed, or has burst

- Roots have completely invaded the drain

- Damaged pipe is causing or threatening damage to surrounding utilities (e.g. water, electric, gas or fiber lines)

- Fastening materials or other components on existing pipe don’t allow for trenchless repair

We will always perform a video drain inspection first, to determine the best route forward. If our expert technicians decide that a trench is necessary, we will dig it right alongside the existing sewer line. Once the broken and damaged lines are repaired, we will backfill with the preexisting soil.

Putting a trench through your property will allow us to tackle these difficult issues and get your sewer line flowing again. That said, digging with heavy duty equipment can do a number on your yard, landscape, and garden. This method should only be performed when absolutely necessary.

Traditional trenching takes less time than it did in years past, but is still a longer process on the front and back end than trenchless sewer drain repair. Be prepared to tackle landscaping, deck, patio, sidewalk or driveway repairs following a trenched sewer line installation.

Trenchless Sewer Drain Repair

When trenching isn’t a necessity, we will recommend our trenchless sewer drain repair. Trenchless excavation will save property owners time and money and result in a painless sewer line replacement with no destruction of yard, landscaping, or hardscaping necessary!

We create a pipe within the existing pipe using cured-in-place pipe (CIPP) to reline and repair the damaged sewer pipe.

How Does Trenchless Sewer Drain Repair Work?

Sewer drain repair using the CIPP, or pipe-inside-a-pipe, method involves installing a permanent liner of Thermoplastic Polyurethane (TPU) film that hard sets inside your existing sewer pipe. TPU is a tough, flexible, and low-friction material that resists heat, cold, oils and chemicals common to waste water. This new lining is more durable than the existing pipe and will last for many years to come.

The Process

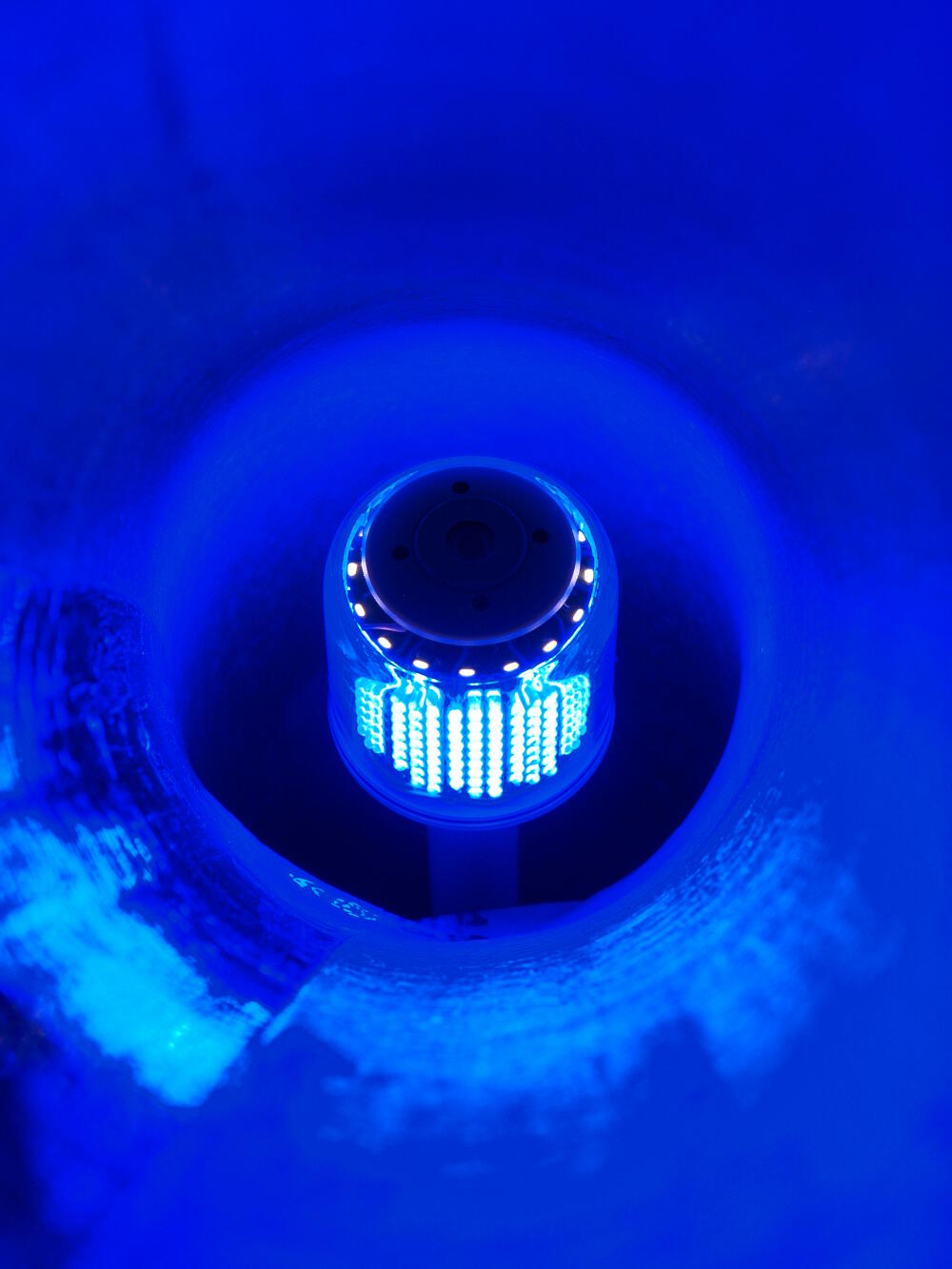

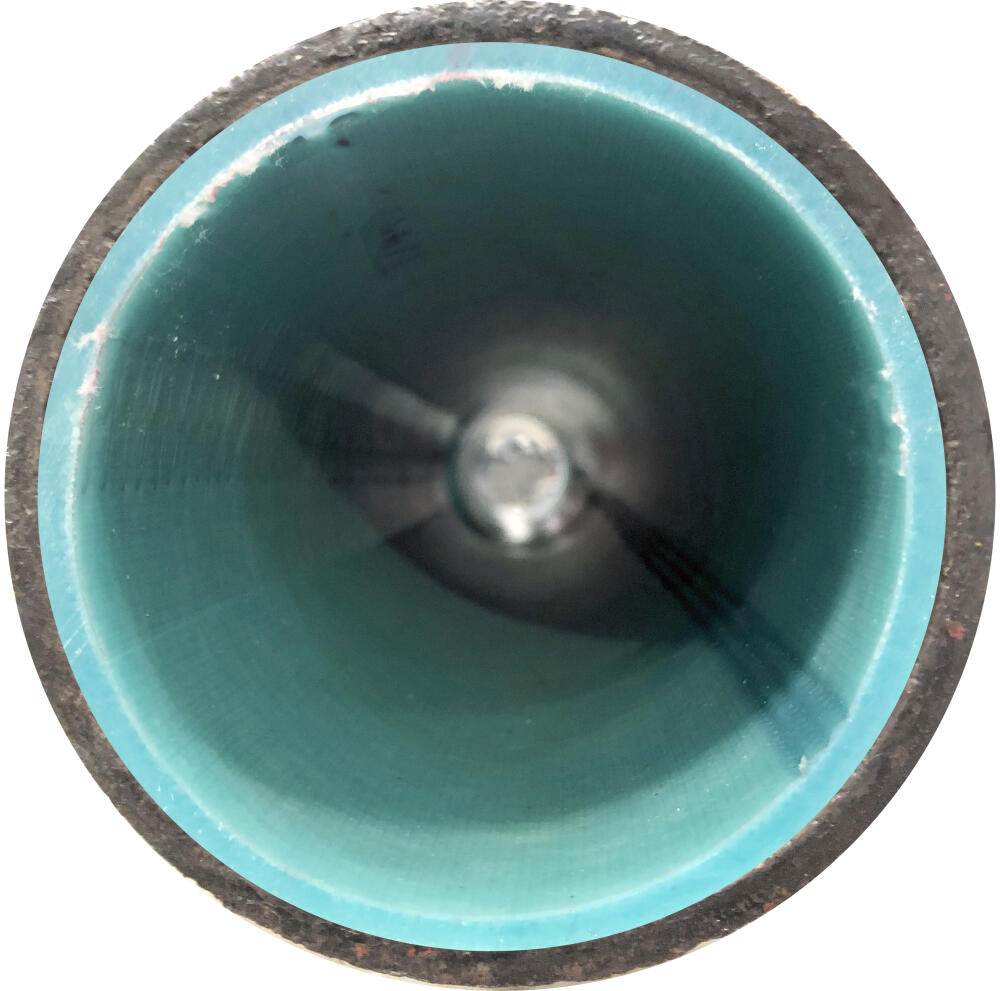

Inspect – Using our sewer and drain camera inspection capabilities, we fully inspect the existing sewer drain to get a handle on the locations and extent of damage. We make note of any cracks, blockages, or root clogs, along with their respective severity. Once we measure the length and diameter of the compromised sections, we have a good idea of what the drain repair will involve.

Clean – Using high-powered water and a technique called hydro jetting, we thoroughly clean the existing sewer drain pipe. This enables us to quickly and efficiently remove roots, soil, buildup, and anything else that could hinder installation.

Repair – There may be areas within the existing sewer drain that are damaged to the point that they do not allow the trenchless equipment to work properly. If that’s the case, we will perform any necessary sewer drain repair prior to installation.

Line – We accurately measure the sewer pipe and then cut a corresponding length of TPU liner. Adhesive is applied, the liner is inserted into the pipe through a designated access point, and it is then fed through the length of the pipe. To ensure that the liner adheres, it is inflated as it cures, helping it to take the shape of the existing sewer drain. The bladder is removed after curing, and the installation is complete.

Reinstatement – After the pipe liner is installed, it needs to be reconnected to the rest of the sewer system. As CIPP liners cure, any lateral lines running perpendicular to the original sewer line are sealed off. Reinstatement is the process of reconnecting these, using a CCTV camera to locate the pipes and a remote-operated, robotic lateral reinstatement cutter to create a new opening for wastewater to flow. Once the pilot hole is routed, the cutter is fitted with an attachment that allows it to file down the TPU lining flush with the lateral opening.

To install the permanent liner, technicians typically only need to dig a small access point to insert the liner material. In total, the entire process only takes about one day, depending on the scale and complexity of the project. At Sewer Cleaning Company, we know that every hour spent without access to water or sewer lines is bothersome and frustrating, so we work efficiently to get your property back up and running as soon as possible.

Trenchless Sewer Lining For Your Cleveland Home Or Small Business

Whatever your sewer drain repair needs, there is most likely a trenchless method that will work for you. At the Sewer Cleaning Company, we use two main methods to repair clients’ broken or damaged drains in both residential and commercial settings, but both methods fall within the umbrella of cured in place pipe (CIPP).

- Continuous Inversion with Robotic Branch Reinstatements: This method is used to install horizontal and vertical lines in tall buildings and can effectively address the potential for gaps from old fittings. Lines can be anywhere from 2” to 24” in diameter, and only one access point is required for installation. Since the lining material is saturated with epoxy that cures on the outside of the liner, it prevents slipping and shifting in vertical applications.

- Pull in Place (PIP): PIP structural pipe liner can be made using felt, fiberglass, or another material and are also saturated with epoxy prior to installation. Unlike other CIPP applications, where the liner is pushed through using air pressure, PIP lining is pulled or winched through pipes, where it will cure and form a new pipe surface. Because the liner is pulled through, it can be localized to a small damaged area and means that total replacement is not always necessary to fix an issue. PIP liners can also have an additional layer that provides extra reinforcement and support and can be used with almost any existing pipe material. PIP installation is typically only performed in horizontal lines of 2-24” in diameter and installation requires two access points.

Whether you opt for continuous inversion or PIP, both methods allow for precise repairs and flexible installation, whatever the configuration of your property’s sewer system.

Where Can You Use Trenchless Sewer Drain Repair?

Trenchless sewer repair can be used in countless applications, including:

- Vertical Stacks

- Branch Lines

- Underground Main Lines

- Lateral Lines

- Rainwater Leaders

- Underground Storm Lines

Sewer Drain Repair For Specific Pipe Materials

Trenchless sewer pipe repair can be performed on a variety of pipe types and sizes, and in a variety of soil and site conditions. That said, some materials will better lend themselves to this method of sewer drain repair than others.

Technically, trenchless technology is compatible with a variety of pipe materials, such as:

- Cast Iron

- Clay

- PVC (and other plastics)

- Concrete

- Copper DWV

- Steel

However, some materials can become problematic. For instance, clay pipes were the norm for homes built prior to 1980. Because they only have a reasonable life expectancy of about 50 years, replacement is likely around the corner. It is inevitable that clay pipes will break with shifting soils, clog with invading tree roots, or become susceptible to any other number of naturally hazardous conditions that come with time. Replacing, repairing, or lining clay pipes with TPU lining materials is possible, so long as the situation is addressed early on, before the pipes are completely compromised. Once that happens, digging is the only option for clay sewer drain repair or replacement.

Cast iron pipes have much the same story as clay–they are designed to last 50 years, and after that they will inevitably need to be replaced or at least repaired. Cast iron is a reactive metal that is prone to rust and corrosion. Over time, these forces will break down the pipes, leading to cracking, crumbling, breaking, and leaks. If a potential problem is identified early on, you can use trenchless methods to line old pipes. If not, and they are past the point of saving, digging will become a necessity to reinstate a working sewer system.

Orangeburg pipes were used in the mid 20th century as an alternative to cast iron, however they still only have a 50 year lifespan. This bituminized fiber pipe was touted as being corrosion resistant but the material has its own problems. It is very brittle and prone to water absorption and deformation under pressure. Tree roots are also a key reason why Orangeburg pipes fail. Repair is possible, if the problem is caught early on. Otherwise, digging is the only way to repair or replace Orangeburg pipes.

If you aren’t sure what material the pipes on your property are made of, or you’re wondering if trenchless sewer drain repair is a viable option for you, your best bet is to contact the team at Sewer Cleaning Company. Our expert technicians will be able to guide you toward the best and most sensible decision.

What Are The Advantages Of Trenchless Sewer Drain Repair?

Besides having their sewer system in good working order again, customers cite the following advantages as their top reasons for choosing trenchless sewer drain repair:

- No digging on their property

- Preserving the home’s interior

- Minimizing damage to landscaping, lawn, and hardscaping

- An increase in pipe flow capacity

- Specialized lining material keeps tree roots at bay

- Trustworthy guarantee backed by a reliable company